The Impact Of Blockchain On The Manufacturing Industry

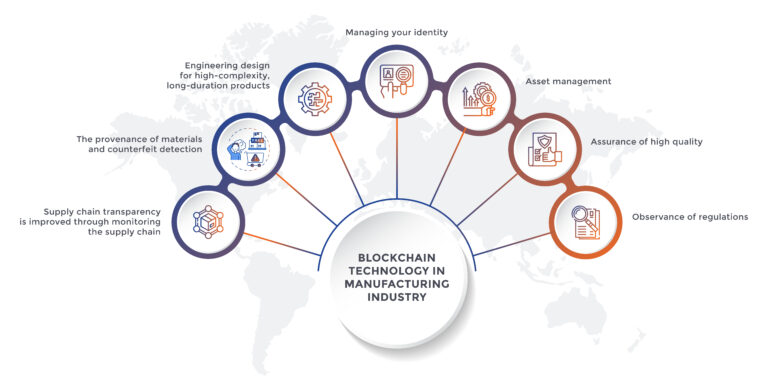

The manufacturing industry is facing a wave of disruption, and blockchain is at the forefront of this change. This revolutionary technology offers the potential to transform how companies manufacture, track, and manage their products and supply chains. By leveraging the decentralized, transparent, and secure nature of blockchain, manufacturers can unlock new levels of efficiency, traceability, and trust, opening up a world of possibilities for innovation and growth.

Introduction

The manufacturing industry, long known for its reliance on traditional methods and systems, is on the cusp of a digital transformation. The rise of Industry 4.0, fueled by technologies like artificial intelligence, the Internet of Things (IoT), and cloud computing, has created a landscape where interconnectedness, data-driven decision making, and real-time visibility are essential for success. Amidst this technological revolution, blockchain stands out as a game-changer, offering solutions to some of the industry’s most pressing challenges.

Traditionally, manufacturing processes have been plagued by inefficiencies, lack of transparency, and vulnerabilities in supply chains. Counterfeit products, product recalls, and supply chain disruptions are just a few examples of the consequences of these issues. Blockchain, with its ability to create an immutable and tamper-proof record of transactions, can address these challenges by providing a secure and transparent platform for tracking products, materials, and transactions throughout the entire supply chain.

Supply Chain Management

Blockchain can revolutionize supply chain management by offering a secure, transparent, and efficient platform for tracking products and materials from origin to end-user. This enhanced visibility allows manufacturers to:

- Improve traceability: Each product can be assigned a unique identifier on the blockchain, allowing manufacturers to track its journey through the supply chain. This transparency helps to combat counterfeiting and ensures the authenticity of products.

- Enhance accountability: All transactions and data related to a product are recorded on the blockchain, providing a permanent and immutable record. This accountability makes it easier to identify and address any issues that may arise within the supply chain.

- Optimize inventory management: Blockchain can provide real-time inventory data, enabling manufacturers to optimize stock levels, reduce waste, and ensure timely delivery of goods.

- Reduce costs and improve efficiency: By streamlining processes and eliminating the need for intermediaries, blockchain can reduce costs and improve overall efficiency within the supply chain.

Production Optimization

Blockchain can be used to optimize production processes, enabling manufacturers to:

- Improve resource allocation: By tracking the flow of materials and resources through the production process, blockchain can help manufacturers optimize resource allocation, reduce waste, and improve efficiency.

- Enhance quality control: Blockchain can be used to record data related to product quality, including inspection results, testing data, and manufacturing parameters. This helps to ensure consistency and improve product quality.

- Reduce downtime: By tracking maintenance records and identifying potential problems, blockchain can help manufacturers reduce downtime and maintain optimal production levels.

- Enable collaborative manufacturing: Blockchain can facilitate collaboration between manufacturers, suppliers, and other stakeholders, enabling them to share data and optimize production processes across the supply chain.

Smart Contracts and Automation

Smart contracts are self-executing agreements written on the blockchain, offering a secure and automated way to manage contracts and agreements within the manufacturing industry. This technology can be used to:

- Automate processes: Smart contracts can automate tasks such as purchase orders, payment processing, and logistics management, reducing the need for manual intervention and improving efficiency.

- Ensure compliance: Smart contracts can enforce contractual obligations and ensure compliance with regulations, reducing the risk of legal disputes and financial losses.

- Streamline payments: Blockchain-based payment systems allow for faster, more secure, and lower-cost payments between manufacturers, suppliers, and other stakeholders.

- Enable new business models: Smart contracts can enable new business models such as peer-to-peer manufacturing and decentralized supply chains, empowering smaller players and fostering innovation.

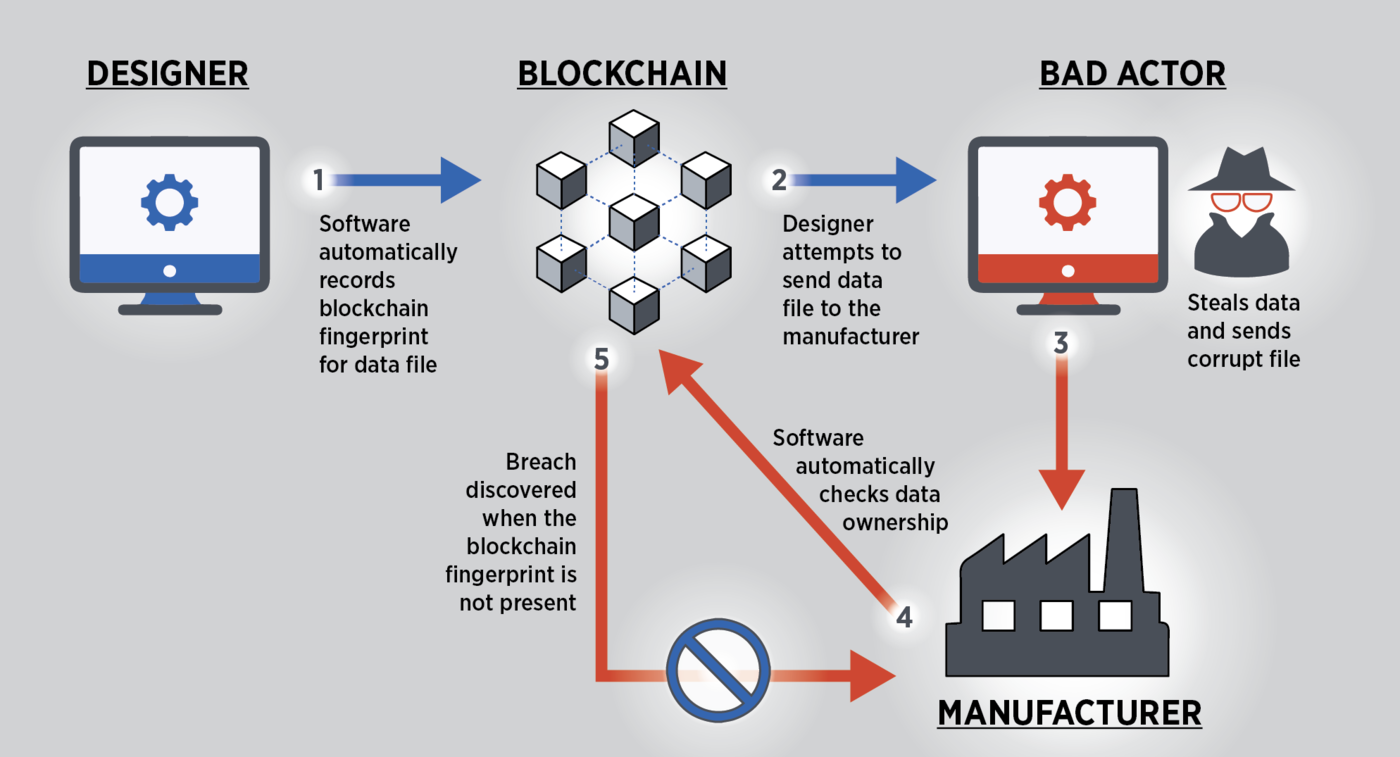

Product Authentication and Counterfeit Prevention

Counterfeit products are a significant problem for manufacturers, costing businesses billions of dollars annually. Blockchain can provide a solution by creating a system for tracking and authenticating products, ensuring their legitimacy:

- Immutable product history: Each product can be assigned a unique identifier on the blockchain, creating an immutable record of its origin, manufacturing process, and journey through the supply chain.

- Real-time verification: Consumers can use a mobile app to scan a product’s unique identifier and verify its authenticity, providing them with confidence in their purchase.

- Reduced counterfeiting: The tamper-proof nature of blockchain makes it extremely difficult for counterfeiters to create and distribute fake products, as their authenticity can be easily verified.

- Improved brand reputation: By combating counterfeiting and ensuring product authenticity, blockchain helps manufacturers protect their brand reputation and build trust with consumers.

Conclusion

The impact of blockchain on the manufacturing industry is profound and multifaceted. By leveraging this transformative technology, manufacturers can overcome traditional challenges, unlock new possibilities, and create a more efficient, transparent, and sustainable future. From supply chain management to production optimization and product authentication, blockchain offers a wide range of benefits that can enhance competitiveness, reduce costs, and improve customer satisfaction.

As the technology continues to evolve, we can expect to see even more innovative applications of blockchain in the manufacturing industry. From smart factories and decentralized production networks to new business models and enhanced customer experiences, blockchain has the potential to transform the industry from the ground up. Manufacturers who embrace this technology and leverage its capabilities will be well-positioned to thrive in the digital age and gain a competitive advantage in the global marketplace.